HYDRAULIC DOCK LEVELER – HDL01ND

It is a connection device between the container floor or a different transport vehicle with the floor of the warehouse / receiving area. Support the circulation of goods from the warehouse to the vehicle’s trunk (and vice versa) safely, effectively and with high productivity, shortening time and saving costs for businesses.

Hydraulic Dock Leveler – HDL01ND uses 1 hydraulic cylinder operated through the controller with simple operation. Equipped with a hydraulic cylinder for flexible lifting operations. Ability to resist deformation, and minimize problems during operation.

ADVANTAGES

- Cost savings: Save time – labor and increase safety when goods rotation…

- Durable operation: The material is able to withstand fluctuations of external environmental conditions.

- Anti-slip: Made of wear-resistant stainless steel, the surface of the steel plate helps prevent slipping.

- Reducing slope: When there is a large gap between the truck floor and the floor of the warehouse with a large size, it will help reduce the slope when the lip Dock opens connecting to the truck floor.

- Safety device: Safety lock valve, control the lifting and lowering movement, limit risk during control.

- Diverse for all types of vehicle trunks.

- Easy to install and operate (suitable for many users).

- Meet food safety standards: Produced according to European technology standards. Helping the factory to meet the safety standards in production operations: ISO 14000, ISO 45001: 2018, ROHS, HACCP, GMP…

Packing in wooden/cotton/PE film carton.

|

|

|

|

|

|

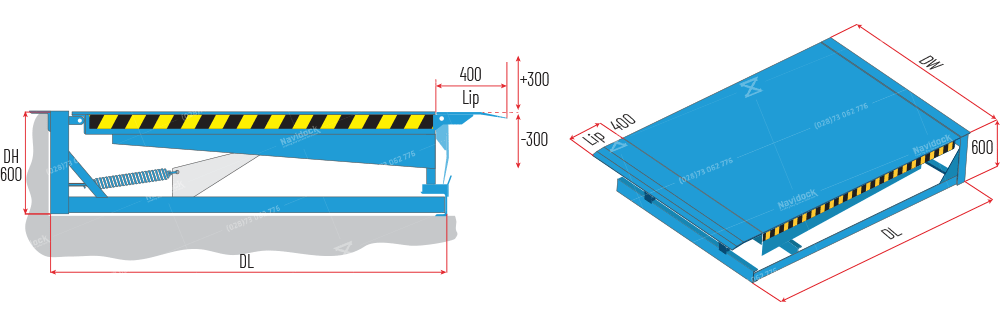

| Model | Lifting Platform Dimension (mm) | Pit Dimension (mm) | Lip lift/lowering range (mm) | ||||||

| DW | DL | DH | Lip | PW | PL | PH | Raising | Lowering | |

| HDL-S106ND20186 | 1800 | 2000 | 600 | 400 | 1840 | 2010 | 610 | +300 | -300 |

| HDL-S106ND25186 | 1800 | 2500 | 600 | 400 | 1840 | 2510 | 610 | +300 | -300 |

| HDL-S106ND20206 | 2000 | 2000 | 600 | 400 | 2040 | 2010 | 610 | +300 | -300 |

| HDL-S106ND20256 | 2000 | 2500 | 600 | 300 | 2040 | 2510 | 610 | +300 | -300 |

| HDL-S106ND20306 | 2000 | 3000 | 600 | 400 | 2040 | 3010 | 610 | +300 | -300 |

|

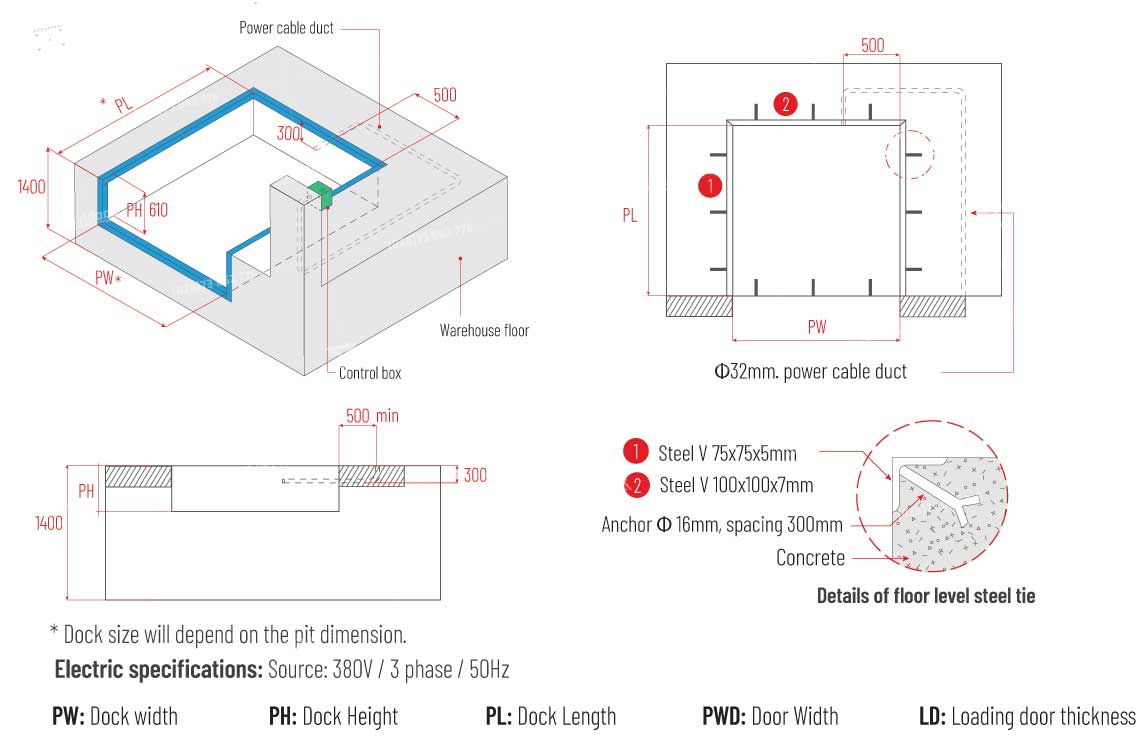

DW: Dock width, DH: Dock height, DL: Dock length excluded, PW: Pit width, PH: Pit height, PL: Pit length

|

|||||||||

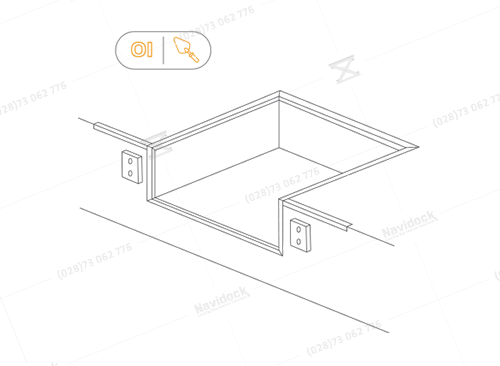

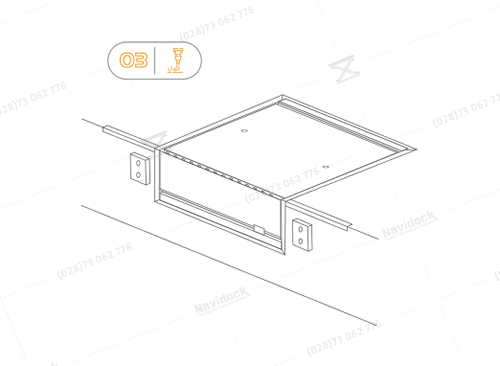

Step 1: Build and complete the Dock pit

Build and complete the Dock pit in accordance with the selected Dock size. Iron frame V around the edge of the pit.

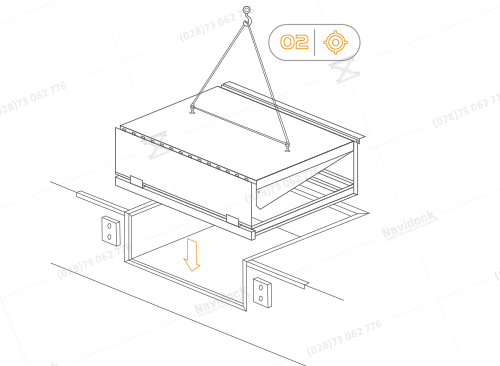

Step 2: Put the Dock in the installation position

Use a forklift or crane to put the Dock into the Dock pit. Depending on the mounting terrain, the Dock can be placed either vertically or horizontally.

Step 3: Welding to connect the Dock to the pit

Weld the dock frame edge to the V-panel of the Dock pit. Check for sure welds and ensure aesthetics. Check for vibration and safety while operating the Dock.

Related products

-

Model HDLTND

1,800$ Select options This product has multiple variants. The options may be chosen on the product page -

Model HDL03ND

1,800$ Select options This product has multiple variants. The options may be chosen on the product page -

Model HDL02ND

1,800$ Select options This product has multiple variants. The options may be chosen on the product page -

Model Mini MDLND

Rated 5.00 out of 5Read more -

Model Mini HDLND

Rated 5.00 out of 51,000$ Select options This product has multiple variants. The options may be chosen on the product page -

Model MDLND

Rated 5.00 out of 51,800$ Select options This product has multiple variants. The options may be chosen on the product page