Model MDLND

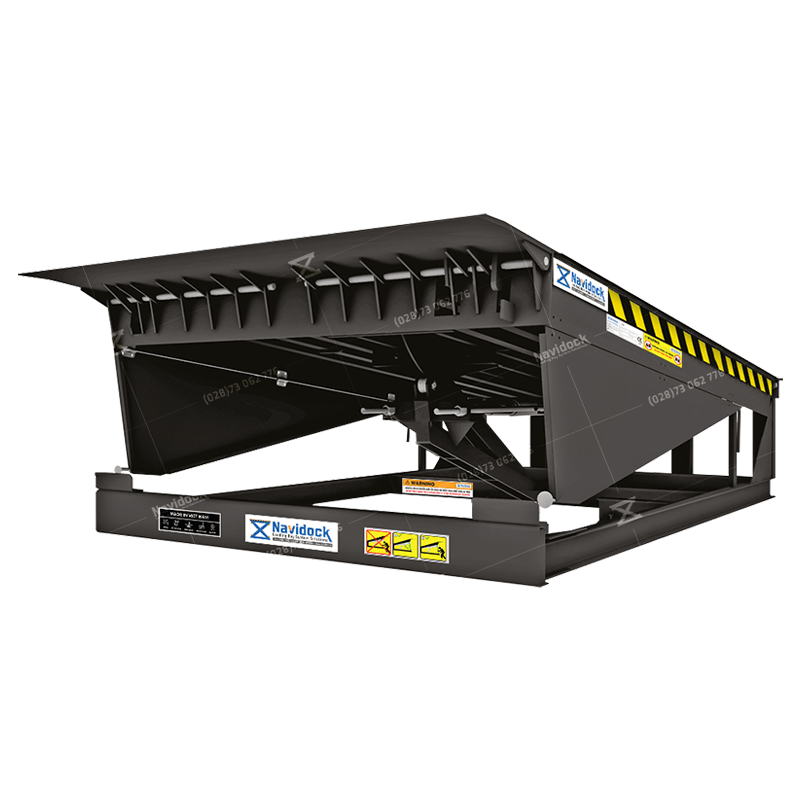

MECHANICAL DOCK LEVELER – MDLND

It is a connection device between the container floor or a different transport vehicle with the floor of the warehouse / receiving area. Support the transportation of goods from the warehouse to the vehicle’s trunk (and vice versa) safely, effectively, and with high productivity, saving time and labor costs..

Mechanical Dock Leveler does not use electricity, operated by a push spring chain system coordinated with the mechanical system, creating a stable and flexible operating mechanism during lifting.

ADVANTAGES

- Durable operation: Designed from high-strength steel material, it can adapt to fluctuations of external environmental conditions.

- Reducing slope: When there is a large gap between the truck floor and the warehouse floor of the warehouse, it will reduce the slope when the lip Dock opens connecting to the truck floor.

- Do not use electricity: MDLND does not use electricity when operating, so it does not consume power sources to help save maximum operating costs for the business.

- Safety device: Safety lock valve, control the lifting and lowering movement, limit risk during control.

- Meet food safety standards: Produced according to European technology standards. Helping the factory to meet the safety standards in production operations: ISO 14000, ISO 45001: 2018, ROHS, HACCP, GMP…

Packing in wooden/cotton/PE film carton.

|

|

|

|

|

|

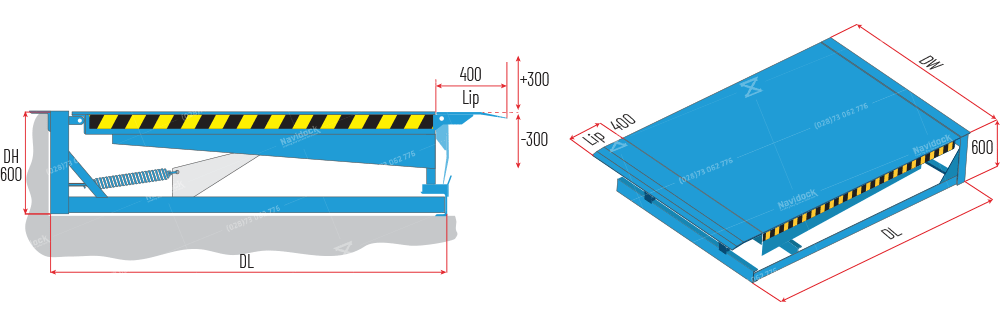

| Model | Lifting Platform Dimension (mm) | Pit Dimension (mm) | Lip lift/lowering range (mm) | ||||||

| DW | DL | DH | Lip | PW | PL | PH | Raising | Lowering | |

| HDL-S106ND20186 | 1800 | 2000 | 600 | 400 | 1840 | 2010 | 610 | +300 | -300 |

| HDL-S106ND25186 | 1800 | 2500 | 600 | 400 | 1840 | 2510 | 610 | +300 | -300 |

| HDL-S106ND20206 | 2000 | 2000 | 600 | 400 | 2040 | 2010 | 610 | +300 | -300 |

| HDL-S106ND20256 | 2000 | 2500 | 600 | 300 | 2040 | 2510 | 610 | +300 | -300 |

| HDL-S106ND20306 | 2000 | 3000 | 600 | 400 | 2040 | 3010 | 610 | +300 | -300 |

|

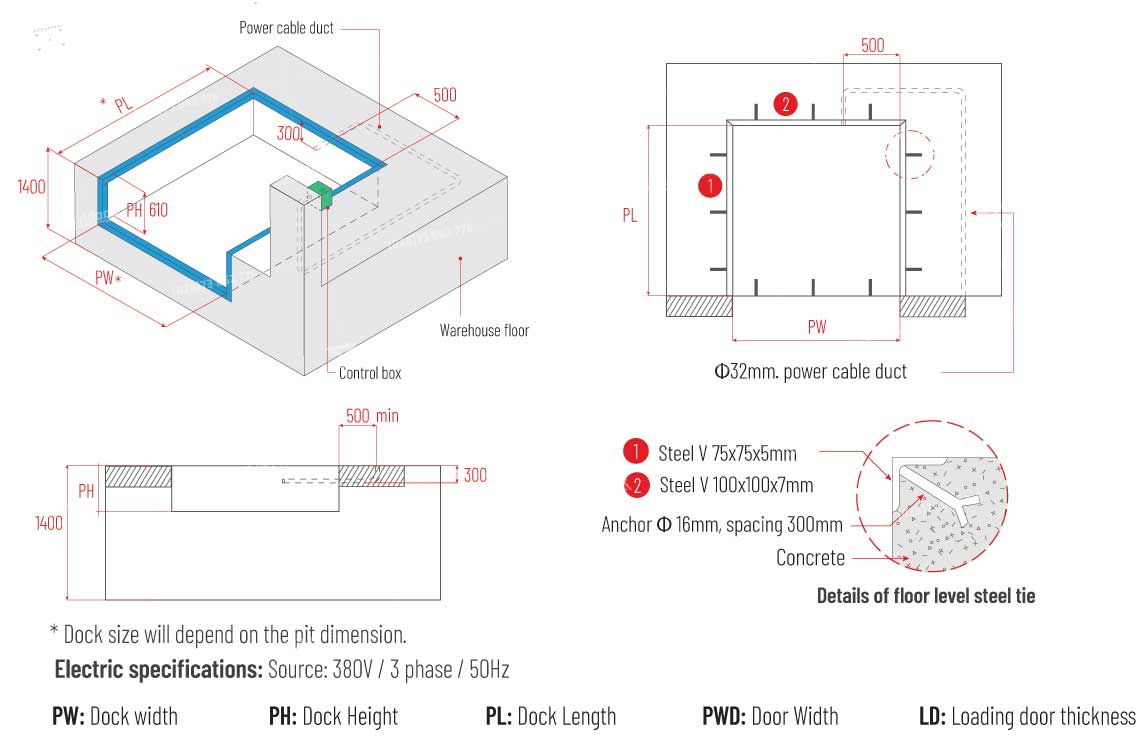

DW: Dock width, DH: Dock height, DL: Dock length excluded, PW: Pit width, PH: Pit height, PL: Pit length

|

|||||||||

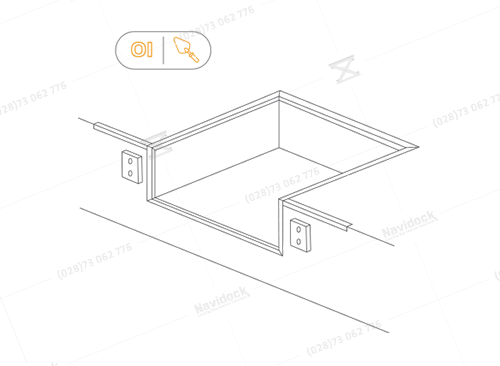

Step 1: Build and complete the Dock pit

Build and complete the Dock pit in accordance with the selected Dock size. Iron frame V around the edge of the pit.

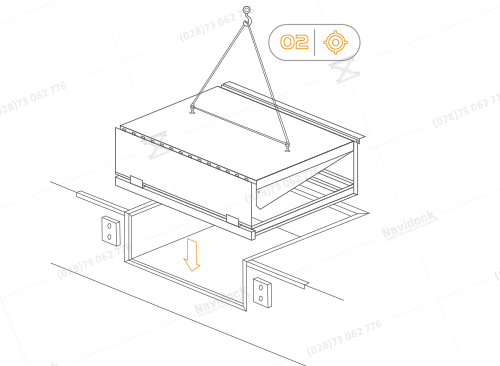

Step 2: Put the Dock in the installation position

Use a forklift or crane to put the Dock into the Dock pit. Depending on the mounting terrain, the Dock can be placed either vertically or horizontally.

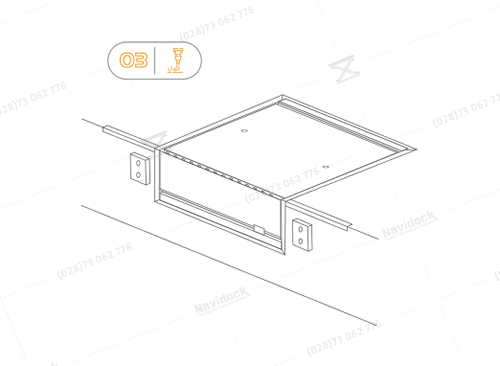

Step 3: Welding to connect the Dock to the pit.

Weld the dock frame edge to the V-panel of the Dock pit. Check for sure welds and ensure aesthetics. Check for vibration and safety while operating the Dock.

Related products

-

Model HDLTND

1,800$ Select options This product has multiple variants. The options may be chosen on the product page -

Model HDL03ND

1,800$ Select options This product has multiple variants. The options may be chosen on the product page -

Model HDL02ND

1,800$ Select options This product has multiple variants. The options may be chosen on the product page -

Model Mini MDLND

Rated 5.00 out of 5Read more -

Model Mini HDLND

Rated 5.00 out of 51,000$ Select options This product has multiple variants. The options may be chosen on the product page -

Model HDL01ND

1,800$ Select options This product has multiple variants. The options may be chosen on the product page